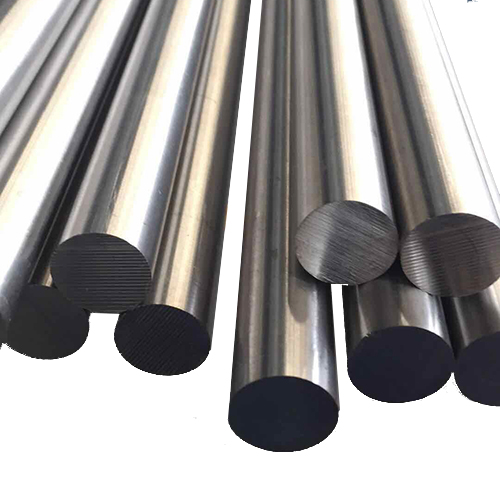

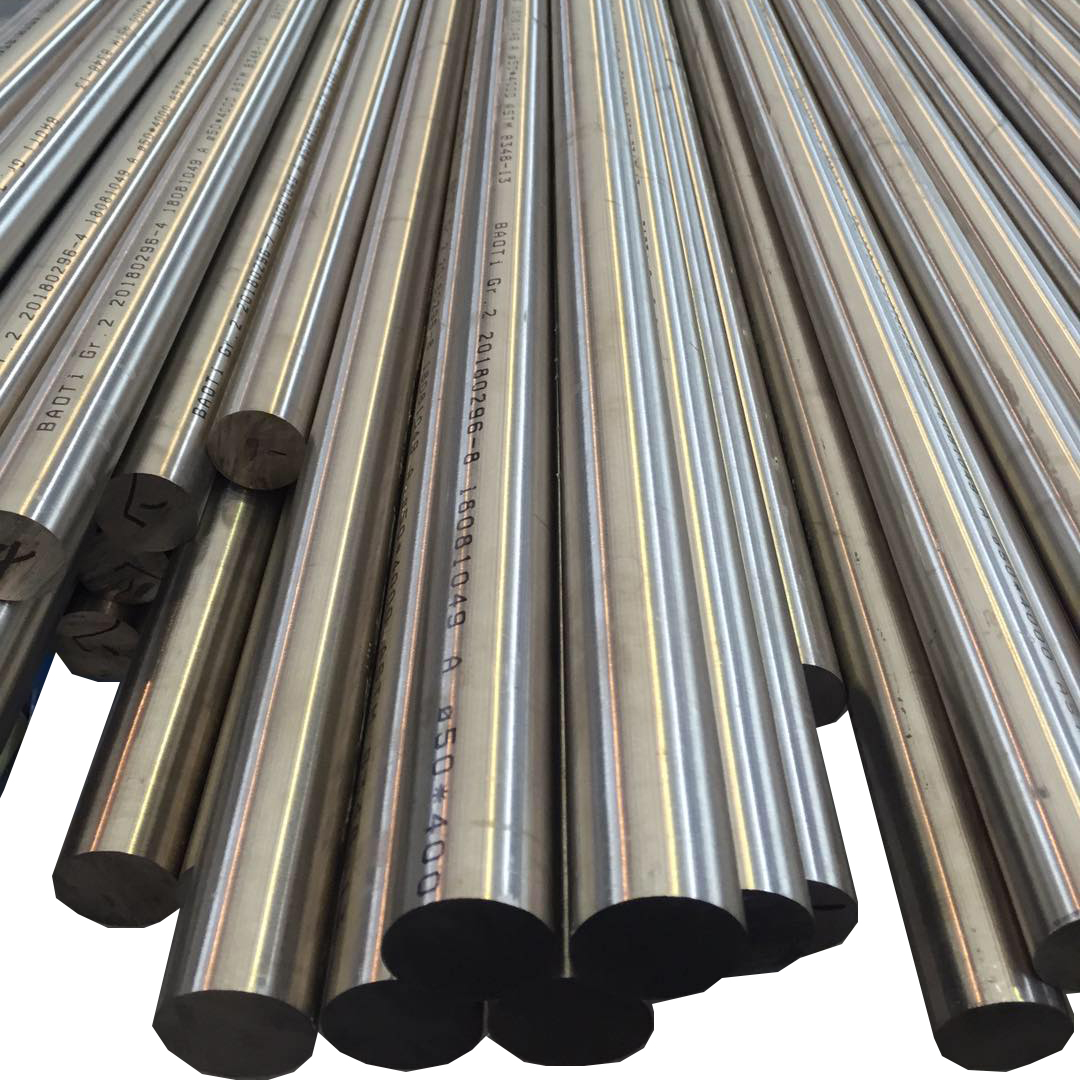

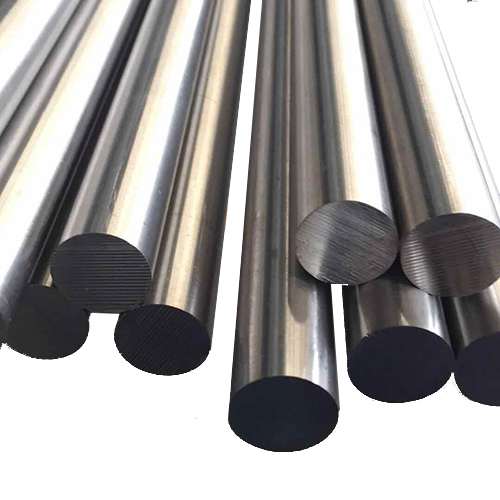

Gallery

1. Implementation standard of titanium rod

GB/ T2965-2007, GB/T13810, Q/ BS5331-91

ASTM B348, ASTM F136, ASTM F67, AMS4928

2. Production brand of titanium rod

Gb: TA1, TA2, TA3, TA7, TA9, TA10, TC4, TC4ELI, TC6, TC9, TC10, TC11

Tag no. : Gr.1, Gr.2, Gr.3, Gr.5, Gr.7, Gr.12

3. Titanium rod production specifications

| SIZE (mm) | TOLERANCE (mm) | OVALITY (mm) |

| 6.35 to 7.94 | +0.13 | 0.20 |

| 7.94 to 11.11 | +0.15 | 0.23 |

| 11.11 to 15.88 | +0.18 | 0.25 |

| 115.88 to 22.22 | +0.20 | 0.30 |

| 22.22 to 25.40 | +0.23 | 0.33 |

| 25.40 to 28.58 | +0.25 | 0.38 |

| 28.58 to 31.75 | +0.28 | 0.41 |

| 31.75 to 34.92 | +0.30 | 0.46 |

| 34.92 to 38.10 | +0.36 | 0.53 |

| 38.10 to 50.80 | +0.40 | 0.58 |

| 50.80 to 63.50 | +0.79, 0 | 0.58 |

| 63.50 to 88.90 | +1.19, 0 | 0.89 |

| 88.90 to 114.30 | +1.59, 0 | 1.17 |

4. Production status of titanium rod:

Hot working condition (R)

Cold working condition (Y)

Annealing state (M)

Solid solution state (ST)

5. Test reference standards

1): GB 228 metal tensile test method

2): GB/T 3620.1 titanium and titanium alloy grades and chemical composition

3): GB/T3620.2 titanium and titanium alloy processing products chemical composition and composition allowable deviation

4): GB 4698 sponge titanium, titanium and titanium alloy chemical analysis method